Digital business transformation examples: 10 Real-World Case Studies

Feb 10, 2026 in Listicle: Examples

Discover digital business transformation examples and how AI, data, and strategy fuel growth with practical, actionable insights.

Not a member? Sign up now

NILG.AI on Oct 21, 2025

Let’s get one thing straight: predictive maintenance isn’t just another buzzword. It’s a game-changing strategy that uses data to fix problems before they actually happen. Instead of waiting for a machine to break down or sticking to a rigid service schedule, you intervene at the perfect time.

This means less guesswork and more foresight, saving you a ton of time and money in the long run.

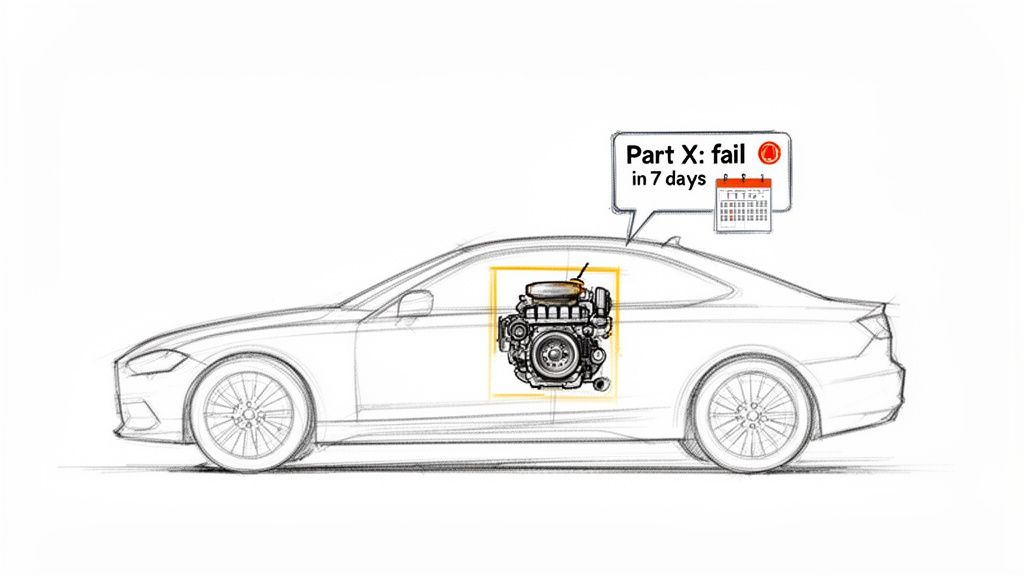

Think about your car’s “check engine” light. Now, imagine if that light didn’t just tell you something was wrong, but instead flashed a message saying, “Heads up, your alternator has an 85% chance of failing next week.” That’s the power of predictive maintenance (PdM) in a nutshell.

It’s a strategic leap from the old ways of doing things.

For decades, maintenance has fallen into two camps. You’ve got the “run it ’til it breaks” method, also known as reactive maintenance. That’s when a machine grinds to a halt, and you’re left scrambling to fix it, usually at the worst possible moment.

Then there’s preventive maintenance, which is definitely a step up. This is your scheduled approach—like changing your car’s oil every 5,000 miles. The problem? You might be changing perfectly good oil or replacing a part that had another year of life in it, just because the calendar said so.

To put it in perspective, here’s a quick breakdown of how these strategies stack up.

| Maintenance Type | Core Principle | Primary Downside |

|---|---|---|

| Reactive | “If it ain’t broke, don’t fix it.” | High cost of unplanned downtime and emergency repairs. |

| Preventive | “Fix it on a fixed schedule.” | Wasted resources on unnecessary maintenance. |

| Predictive | “Fix it right before it breaks.” | Requires an upfront investment in technology and data. |

As you can see, predictive maintenance offers a smarter path forward, avoiding the major pitfalls of the other two approaches.

So, how does it work? Predictive maintenance uses sensors to continuously monitor things like vibration, temperature, and pressure on your equipment. This constant stream of data paints a real-time picture of an asset’s health.

Then, smart algorithms get to work, sifting through that data to find tiny, almost invisible patterns that are the early warning signs of an impending failure.

This changes everything. Your maintenance crew goes from being a reactive fire department to a proactive team that keeps the whole operation running smoothly. You fix equipment on your terms, not when a crisis forces your hand.

You stop wasting money on parts that are still good and avoid the gut-wrenching cost of a full-blown production stoppage. It’s a transition many facilities are already making, often starting with critical systems like their motor control centers. If you’re looking for a deep dive on that topic, guides like Mastering Motor Control Center Maintenance are a great place to start.

Ultimately, getting a handle on predictive maintenance is the first real step toward supercharging your efficiency, making your equipment last longer, and building a serious competitive edge.

So, how does a piece of equipment actually tell you it’s about to break down? It’s not magic. It’s a smart, layered system where a few key technologies work in concert to turn streams of raw data into a clear warning.

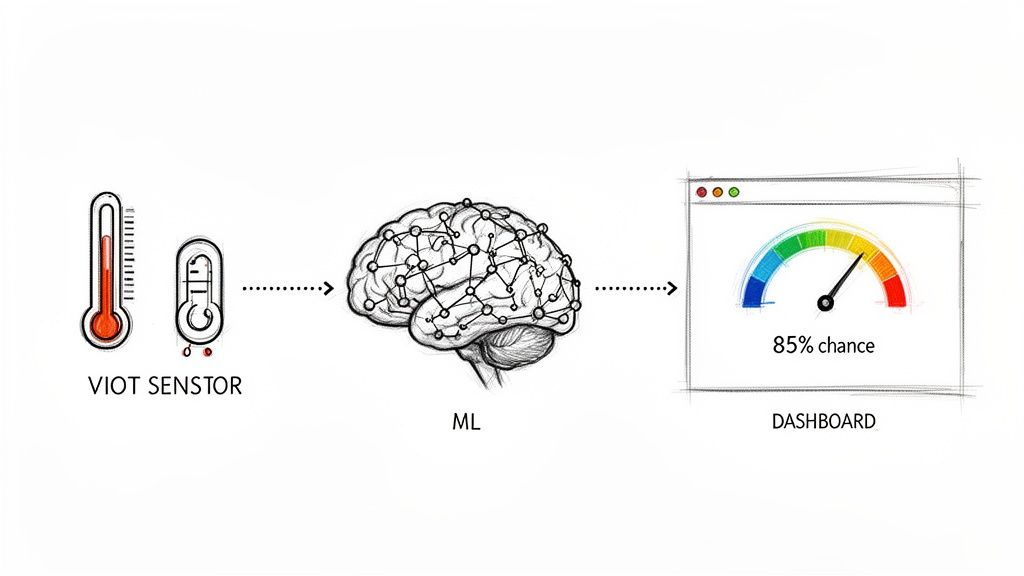

It all starts with data collection. This is where the Internet of Things (IoT) shines. Think of IoT sensors as the digital eyes and ears for your machinery. These small but mighty devices are attached to critical parts, constantly monitoring everything that’s happening.

They track it all—vibration, temperature, pressure, electrical current, oil quality, you name it. Every moment, they generate a massive, continuous flow of data that captures a detailed picture of the machine’s health in real-time. Without that constant feed of information, any attempt at prediction is just a shot in the dark.

Once you have the data, you need something to make sense of it. That’s the job of machine learning (ML) algorithms—the real intelligence behind any predictive maintenance setup. These algorithms are fed huge amounts of historical data, allowing them to learn the unique signature of what “normal” looks like for a specific asset.

They are incredibly good at spotting tiny, subtle changes and patterns that a human would never catch. For example, an ML model might discover that a seemingly harmless 0.5% rise in a motor’s temperature, when combined with a specific new vibration frequency, is a dead giveaway for an impending bearing failure. This analytical horsepower is what truly sets prediction apart from simple monitoring. If you’re curious about the mechanics, you can dive deeper into our guide on machine learning for predictive maintenance.

The goal isn’t just to see data; it’s to understand the story the data is telling. ML models connect the dots between minor operational changes and major future failures, giving you the lead time needed to act.

All this number-crunching is useless if it isn’t presented in a way people can actually use. This is where analytics dashboards and software platforms come in. They serve as the friendly face of the operation, translating complex statistical probabilities into simple, direct alerts for your team.

Instead of drowning you in raw data, a good dashboard gives you a clear insight.

This final step is what connects the data scientists with the technicians on the factory floor. Choosing the right platform is critical, and a look at the top predictive analytics software can show you how different tools are designed to turn data into decisions. This seamless flow—from sensor to analysis to screen—is what makes predictive maintenance a powerful, practical reality.

Knowing the tech behind predictive maintenance is one thing. But what really matters is seeing how it hits your bottom line. This isn’t just another shiny IT project; it’s a strategic shift that can turn your maintenance team from a necessary expense into a profit-boosting powerhouse.

The financial wins start with one massive change: cutting down unplanned downtime. Every minute a critical machine sits idle, money is walking out the door. When you can see a failure coming, you can schedule repairs during planned shutdowns. That keeps the production lines humming and the revenue coming in.

This smarter approach also takes a huge bite out of maintenance costs. Forget replacing parts on a rigid, calendar-based schedule, whether they need it or not. Instead, you only step in when the data tells you a specific component is genuinely on its last legs. It’s a simple change that stops you from throwing money away on perfectly good parts and unnecessary labor.

Let’s talk numbers, because they’re pretty convincing. On average, companies that get this right see some incredible results:

This isn’t just a niche trend. The market for this technology is expected to explode from USD 9.21 billion in 2025 to a massive USD 79.70 billion by 2034. The lockdowns after 2020 actually accelerated this, as companies using remote analytics saw 15-30% efficiency gains in industries where a single day of downtime can cost millions. You can dig into the specifics in this in-depth predictive maintenance market report.

This isn’t just about saving a few bucks here and there; it’s about making your entire operation stronger and more efficient.

By fixing equipment right before it fails, you extend the lifespan of your most expensive assets. This maximizes their value and delays major capital expenditures, freeing up cash for growth and innovation.

Beyond the direct savings, predictive maintenance elevates performance across the board. When you get rid of unexpected interruptions, you create a far more stable and predictable production environment. This translates to better planning, smoother workflows, and ultimately, higher output. It’s important to track these gains, and you can learn more about which operational efficiency metrics to watch.

And let’s not forget safety. An asset on the verge of failure is often a dangerous one. By catching these issues before they turn into accidents, you’re protecting your people from harm. That doesn’t just reduce the risk of costly incidents; it builds a culture of safety and reliability, which is great for morale and performance.

The financial case is clear: predictive maintenance is an investment in stability, efficiency, and long-term success.

Theory is great, but let’s talk about what really matters: how this stuff actually works in practice. Seeing predictive maintenance in action—from a noisy factory floor to 30,000 feet in the air—is where the lightbulb really goes on. This isn’t just a concept; it’s already preventing huge disasters and saving companies a fortune.

Picture a massive smart factory. In the middle of it all, there’s a single robotic arm doing a job that the entire assembly line depends on. If that arm goes down unexpectedly, the whole operation grinds to a halt. We’re talking hundreds of thousands of dollars lost for every single hour of downtime.

Instead of just crossing their fingers and waiting for it to break, the factory is a step ahead.

Sensors attached to the arm’s motors and joints are constantly sending back a stream of data—vibrations, temperature, how much power it’s drawing. An AI model, trained on months of this data, picks up on a tiny, almost invisible shift in the vibration signature. To the human eye, everything looks fine, but the algorithm knows better. It’s the classic tell-tale sign that a critical bearing is starting to wear out.

An alert instantly pops up for the maintenance crew: “Robotic Arm 7 has a 92% chance of bearing failure in the next 72 hours.” They don’t have to drop everything. Instead, they schedule the fix during a planned overnight shift. A $50 bearing is swapped out, and a million-dollar production meltdown is completely avoided.

This same smart approach is being used in all sorts of industries.

Each of these stories follows the same script: a very specific problem is solved with a smart, data-driven solution, and the results are game-changing. It all comes down to having the right strategy and a solid grasp of the available predictive maintenance tools. When you get that right, you can tackle the unique challenges in any industry and turn your operational data into your biggest advantage.

So, you’re ready to move from theory to reality? Getting started with predictive maintenance isn’t about a massive, “boil the ocean” overhaul. It’s a journey that starts small, proves its worth quickly, and then scales up intelligently.

Think of this as a high-level roadmap for business leaders, not a technical manual for engineers. It’s a clear path to turning data-driven insights into tangible business wins.

The whole thing kicks off with one simple question: Where does it hurt the most?

Don’t try to monitor everything at once. The key to a fast, impactful win is to laser-focus on the equipment where an unexpected failure would cause the most financial pain or operational chaos. This could be that one irreplaceable robotic arm on the assembly line, a critical power generator, or your entire fleet of delivery trucks.

By starting with your most valuable, high-impact assets, you guarantee your first project delivers a result that gets everyone’s attention. It’s the best way to build momentum and get the buy-in you need to expand later.

Once you’ve picked your target asset, it’s all about the data. You need to figure out what information actually hints at an upcoming failure. This usually means blending historical maintenance logs (what broke and when) with live operational data from sensors measuring things like vibration, temperature, and pressure.

This is where a lot of projects get bogged down. Working with a data science or AI partner at this stage is a smart move. They can help ensure you’re collecting the right data, not just more data. A solid plan here helps you avoid the classic “garbage in, garbage out” problem and builds a reliable foundation for your predictive models.

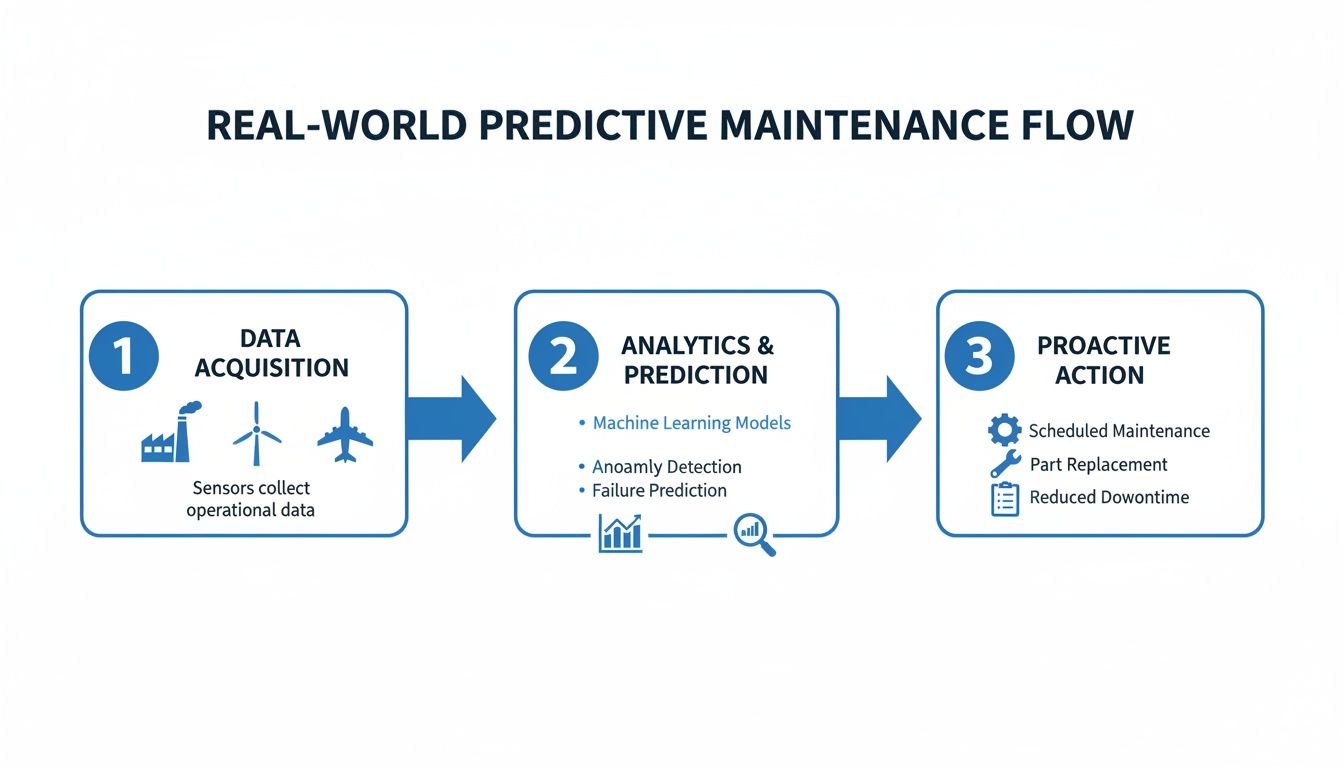

This diagram shows how data flows from different industrial machines to create maintenance alerts that you can actually act on.

As you can see, the process is similar whether the data comes from factories, wind farms, or airplanes—it’s all about turning raw numbers into actions that prevent downtime.

With a clear target and a solid data plan, you’re ready to kick off a pilot project. Think of this small-scale test as your proof of concept. The goal is to show real value—like accurately predicting a component failure and preventing a costly shutdown—without a huge upfront investment.

A successful pilot doesn’t just prove the technology works; it proves the business case and gives you a clear blueprint for expansion. And the opportunity here is massive. The global predictive maintenance market is expected to jump from around $10-12 billion in 2024 to nearly $100 billion by the early 2030s. Companies already on board are cutting unplanned downtime by up to 50% and slashing maintenance costs by 10-40%. You can learn more about these market findings to see the growth potential for yourself.

Once you’ve proven the value on a small scale, you can scale with confidence. You’ll have the data, the process, and the success story needed to roll out predictive maintenance across other critical assets, transforming your entire operation one step at a time.

Getting a predictive maintenance program off the ground is an exciting step, but let’s be real—it’s rarely a straight shot to success. Knowing where the landmines are hidden can help you navigate the journey and avoid the common traps that trip up even the most well-intentioned teams.

One of the biggest showstoppers is poor data quality. Your predictive models are only as good as the data you feed them. If you’re working with incomplete, messy, or irrelevant information, your predictions will be just as unreliable. It’s the classic “garbage in, garbage out” problem.

To get ahead of this, you have to build on a solid data foundation. This is where partnering with an AI and data consulting business can be a game-changer. They can help you figure out which data points actually matter, clean up your historical records, and make sure your sensors are collecting the right stuff from the get-go.

Another common misstep is trying to boil the ocean. Teams get excited and attempt to implement a massive, enterprise-wide system right out of the gate. This approach often leads to blown budgets, frustrating delays, and a burned-out team. The more strategic move is to start small.

Pick one or two critical assets and run a focused pilot project. Nail it there first. A successful pilot gives you a powerful success story to share, which is exactly what you need to build momentum and get buy-in for a larger rollout.

A phased approach isn’t about thinking small; it’s about building a strong, scalable foundation. It lets your team learn, adapt, and show real ROI quickly, which is what paves the way for long-term success.

Finally, don’t forget about the people on the floor. Your maintenance teams are your secret weapon. They have years, sometimes decades, of hands-on experience and know the quirks of your equipment better than any algorithm ever will. Ignoring them is a recipe for disaster.

The boom in IoT has really supercharged our ability to collect data, making real-time failure predictions a reality. This became even more critical post-COVID for managing assets remotely. In fact, manufacturing firms have reported 20-30% cuts in maintenance costs and 10-20% increases in equipment uptime by getting this right. You can find more details on these figures in this market trends report from metatechinsights.com.

As you start digging into what predictive maintenance can do for you, some practical questions always pop up. Here are some straight-talking answers to the things we hear most often from leaders looking to make the switch.

You’d be surprised—you don’t need a mountain of perfect data from day one. A great place to begin is by combining your historical maintenance records with some live sensor data from a handful of your most important machines.

It’s not about the sheer amount of data; it’s about having the right data. You need info that connects the dots between a machine’s condition (like a sudden spike in vibration) and a specific failure (like a bearing giving out). A good data science partner can take a look at what you’ve got, figure out where the gaps are, and help you build a smart plan to collect what’s missing.

Not anymore. Predictive maintenance may have started out in giant industrial plants, but it’s now a completely viable and powerful tool for small and mid-sized businesses, too.

Thanks to cloud computing and more affordable AI platforms, the barrier to entry is much lower. You can kick things off with a small pilot project on one or two of your most valuable assets. It’s a low-risk way to see the return on investment for yourself before going all-in.

Think of it as a smart investment in your own efficiency, not some massive, bank-breaking overhaul. The idea is to start small, prove the value, and then scale up with confidence.

It’s best to think of them as two rungs on the same ladder. Each one gets you a little closer to a fully automated, intelligent system.

At NILG.AI, our specialty is building AI-powered roadmaps that turn your operational data into a real competitive advantage. We work with businesses like yours to put predictive solutions in place that cut costs, make you more efficient, and fuel growth.

Find out how we can help you build a smarter maintenance strategy. Request a proposal

Like this story?

Special offers, latest news and quality content in your inbox.

Feb 10, 2026 in Listicle: Examples

Discover digital business transformation examples and how AI, data, and strategy fuel growth with practical, actionable insights.

Feb 6, 2026 in Resources

Discover the 12 best AI tools for small business success. Our guide covers strategic insights, pros & cons, and how to choose the right AI partner.

Feb 3, 2026 in Guide: How-to

Master customer retention rate calculation with this practical guide. Learn the formulas, see real-world examples, and get actionable tips for business growth.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |