Digital business transformation examples: 10 Real-World Case Studies

Feb 10, 2026 in Listicle: Examples

Discover digital business transformation examples and how AI, data, and strategy fuel growth with practical, actionable insights.

Not a member? Sign up now

NILG.AI on Nov 28, 2025

Outdated processes are more than just inefficient; they’re silent profit killers. Many organizations cling to familiar workflows, unaware that these legacy systems are bleeding cash, frustrating talented teams, and actively stifling growth. You might be paying for sluggish manual data entry, redundant approval cycles, or disconnected software tools without even realizing the full extent of the cost. The “if it ain’t broke, don’t fix it” mindset is a surefire way to get left behind.

This article is your playbook for turning those operational drags into strategic assets. We’re moving past high-level theories to deliver a tactical breakdown of 10 powerful process innovations examples. You won’t find generic success stories here. Instead, we’ll dissect each example, focusing on how AI, automation, and data-driven strategies can be applied in real-world business scenarios, particularly for consulting and service-oriented firms.

Get ready to explore replicable strategies and actionable takeaways. We’ll break down the what, the why, and the how for methodologies like Lean, Six Sigma, Agile, and Robotic Process Automation (RPA). You’ll learn to identify hidden inefficiencies in your own operations and gain a clear roadmap for implementing changes that deliver measurable results. Let’s dive in and transform your processes from a liability into a competitive advantage.

Robotic Process Automation (RPA) is a game-changer for businesses bogged down by repetitive, manual tasks. It uses software “bots” to mimic human actions on a computer, like logging into applications, moving files, filling out forms, and extracting data from documents. Think of it as a digital workforce that handles the boring stuff, freeing your human team for more strategic work.

This is one of the most accessible process innovations examples because it doesn’t require overhauling your entire IT infrastructure. RPA bots interact with systems just like people do, through the user interface, making implementation faster and less disruptive than traditional API-based automation.

An AI consulting firm struggled with a manual, error-prone invoicing process. Each month, project managers would manually compile timesheets, cross-reference them with client contracts, and generate invoices. The process took dozens of hours and often contained errors, leading to payment delays. By implementing an RPA bot, the firm automated the entire workflow. The bot now extracts data from timesheet software, validates it against contract terms in their CRM, and generates accurate invoices in minutes. This not only saved significant administrative time but also improved cash flow by reducing invoice disputes.

RPA is ideal for processes that are high-volume, rule-based, and use structured data. It’s a quick win for efficiency gains in areas like finance, HR, and customer service.

RPA serves as a powerful entry point into automation, but it truly shines when combined with AI and machine learning. To see how this technology evolves, you can dive deeper into intelligent process automation.

Six Sigma is a disciplined, data-driven methodology designed to eliminate defects and reduce variability in any business process. Its core goal is to achieve near-perfect quality, aiming for no more than 3.4 defects per million opportunities (DPMO). It’s less about a specific technology and more about a rigorous, statistical approach to problem-solving and process refinement.

While originating in manufacturing, Six Sigma stands as one of the most powerful process innovations examples for service-based industries too. It provides a structured framework (often DMAIC: Define, Measure, Analyze, Improve, Control) to identify the root cause of problems, rather than just treating the symptoms, leading to sustainable, high-impact improvements.

A data analytics consultancy discovered that a significant portion of its project time was spent cleaning and correcting client data before analysis could even begin. This “defect” in their intake process was eroding profit margins. Using the Six Sigma DMAIC framework, they defined the problem (poor data quality), measured the frequency and type of errors, and analyzed the root causes—unclear client submission guidelines and inconsistent data formats. They improved the process by creating a standardized data submission template and an automated validation tool. The control phase involved monitoring data quality scores for all new projects. This initiative reduced data prep time by over 40%, allowing consultants to focus on high-value analysis rather than data janitorial work.

Six Sigma is most effective for complex problems where the root cause isn’t obvious and requires deep statistical analysis to uncover. It’s a commitment to a culture of continuous improvement, not a one-off project.

Business Process Management (BPM) is a holistic approach to optimizing business workflows. Instead of looking at tasks in isolation, BPM treats processes as strategic assets that can be continuously analyzed, improved, and automated to align with organizational goals. It’s about stepping back, seeing the entire journey a task takes through your company, and making that journey smarter, faster, and more efficient.

This discipline is one of the foundational process innovations examples because it provides a framework for systematic improvement. BPM isn’t just a one-time fix; it’s a continuous cycle of modeling, implementing, monitoring, and optimizing processes to adapt to changing market demands and customer needs.

A B2B technology consulting firm used BPM to map its entire sales process, from lead generation to client onboarding. The “as-is” map revealed major bottlenecks: proposal generation was slow, contract reviews involved multiple handoffs via email, and client onboarding was inconsistent. Using a BPM platform, they redesigned the process. Now, when a lead is qualified, the system automatically generates a proposal using standard templates. The contract is routed for digital signatures via a defined workflow, and once signed, it triggers an automated onboarding sequence for the project management team. This BPM initiative cut their sales cycle time by 30% and ensured a consistent, professional experience for every new client.

BPM is perfect for core, cross-departmental processes that directly impact customer value or operational costs, like order-to-cash or new product development. Its principles are often integrated with agile methodologies to increase responsiveness.

Agile Process Management throws the traditional, rigid “plan everything upfront” model out the window. It’s an iterative and flexible approach that prioritizes rapid delivery, continuous feedback, and adapting to change on the fly. Born from software development, its principles of breaking big projects into small, manageable cycles (sprints) are now transforming marketing, HR, and product development across all industries.

This method stands out as one of the most human-centric process innovations examples because it champions collaboration and customer feedback over rigid processes. Instead of a single, long development phase, Agile teams work in short bursts, continuously delivering value and adjusting their direction based on real-world results and stakeholder input.

An AI consulting firm adopted Agile to manage its complex client projects. Previously, they used a “waterfall” approach, spending months on a detailed project plan that often became obsolete as client needs evolved. By switching to an Agile (Scrum) framework, they broke projects into two-week “sprints.” At the end of each sprint, they deliver a functional piece of the solution, like a working data model or a dashboard prototype. This allows the client to provide immediate feedback, ensuring the final product is perfectly aligned with their needs. The result was higher client satisfaction, less rework, and a more predictable delivery schedule.

Agile is perfect for complex projects where requirements are likely to change. It thrives in dynamic environments where speed and customer satisfaction are top priorities.

True agility is a cultural shift, not just a process change. To get started, it’s vital to invest in training and understand the foundational principles laid out in the original Agile Manifesto.

Total Quality Management (TQM) is a deep-seated philosophy that ingrains quality into every fiber of an organization’s operations. It shifts the responsibility for quality from a single inspection department to every single employee, from the CEO to the front line. The core idea is that continuous, incremental improvements across all functions lead to superior products, services, and customer satisfaction.

This methodology is one of the most foundational process innovations examples because it transforms a company’s culture, not just a single workflow. TQM focuses on long-term success through customer satisfaction, achieved by integrating all organizational functions like marketing, finance, design, and engineering to focus on a common goal: quality. It’s about building a system that prevents errors from happening in the first place.

A service provider’s call center was plagued by low customer satisfaction scores and high agent turnover. They initiated a TQM program focused on improving service quality. Instead of just monitoring call times, they empowered agents to solve customer problems on the first call, providing them with better training and more authority. They created cross-functional “Quality Circles” with agents, team leads, and IT staff to identify the root causes of common customer complaints, such as billing system errors. By addressing these systemic issues and focusing on employee empowerment, they saw a 30% increase in first-call resolution rates and a significant boost in both customer and employee satisfaction.

TQM is best suited for organizations committed to a long-term cultural shift toward excellence, rather than just seeking a quick fix. It’s powerful in manufacturing, healthcare, and service industries where consistency and customer trust are paramount.

Robotic Process Automation (RPA) is a game-changer for businesses bogged down by repetitive, manual tasks. It uses software “bots” to mimic human actions on a computer, like logging into applications, moving files, filling out forms, and extracting data from documents. Think of it as a digital workforce that handles the boring stuff, freeing your human team for more strategic work.

This is one of the most accessible process innovations examples because it doesn’t require overhauling your entire IT infrastructure. RPA bots interact with systems just like people do, through the user interface, making implementation faster and less disruptive than traditional API-based automation.

An AI consulting firm struggled with a manual, error-prone invoicing process. Each month, project managers would manually compile timesheets, cross-reference them with client contracts, and generate invoices. The process took dozens of hours and often contained errors, leading to payment delays. By implementing an RPA bot, the firm automated the entire workflow. The bot now extracts data from timesheet software, validates it against contract terms in their CRM, and generates accurate invoices in minutes. This not only saved significant administrative time but also improved cash flow by reducing invoice disputes.

RPA is ideal for processes that are high-volume, rule-based, and use structured data. It’s a quick win for efficiency gains in areas like finance, HR, and customer service.

RPA serves as a powerful entry point into automation, but it truly shines when combined with AI and machine learning. To see how this technology evolves, you can dive deeper into intelligent process automation.

Design Thinking is a process innovation framework that flips traditional problem-solving on its head. Instead of starting with a solution or a piece of technology, it begins with deep empathy for the end-user. It’s a human-centered methodology that uses cycles of prototyping, testing, and iterating to create processes, products, and services that people actually want and need.

This approach is one of the most powerful process innovations examples because it forces you to challenge assumptions and redefine problems from a user’s perspective. It’s less about a linear, rigid plan and more about a flexible, iterative journey to uncover the best possible solution.

A boutique management consultancy used Design Thinking to tackle its inconsistent and confusing client onboarding experience. Instead of just tweaking their existing process, they started by interviewing recent clients to understand their anxieties and expectations. This “empathy” phase revealed that clients felt overwhelmed by initial data requests and unsure of the project timeline. Armed with these insights, the firm prototyped a new process that included a visual project roadmap, a single point of contact, and a “Week 1 Kickstart Kit” with clear instructions. They tested this new process with a pilot client, gathered feedback, and iterated. The result was a streamlined, client-centric onboarding process that set a positive tone for the entire engagement.

Design Thinking is perfect for tackling ambiguous or complex problems where the user experience is paramount. Use it to innovate customer service workflows, internal HR processes, or new product development cycles.

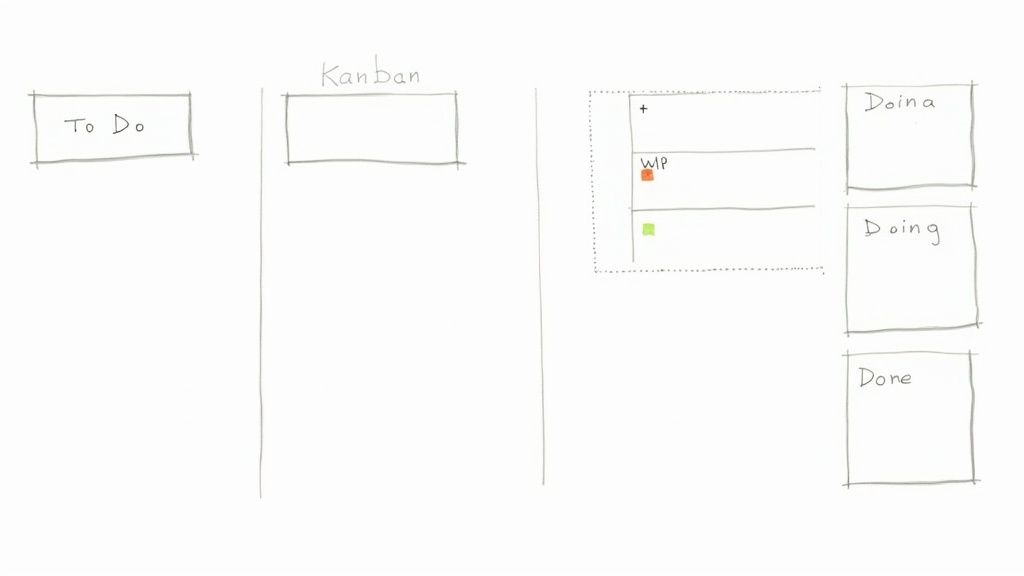

The Kanban system is a visual management method for controlling and improving work across human systems. Originating from Toyota’s manufacturing process, this approach uses visual cues, typically cards on a board, to represent work items and their flow through various stages. It’s designed to limit work-in-progress (WIP), identify bottlenecks, and maximize efficiency.

This method is one of the most powerful process innovations examples because of its simplicity and flexibility. Unlike rigid methodologies, Kanban doesn’t prescribe specific roles or processes; instead, it provides a framework to visualize your existing workflow and incrementally improve it. This makes it adaptable for everything from software development to marketing and warehouse management.

A digital marketing agency’s content creation process was chaotic. Writers were overloaded, editors were bottlenecks, and stakeholders had no visibility into when content would be ready. They implemented a simple digital Kanban board with columns for “Backlog,” “Writing,” “Editing,” “Client Review,” and “Published.” Each blog post or case study became a card. By setting a WIP limit on the “Editing” column, they forced the team to clear the editing backlog before new content was submitted. This simple change immediately highlighted the editing bottleneck, leading them to reallocate resources. The visual board gave everyone, including clients, real-time visibility, reducing status-update emails and improving the flow of content delivery.

Kanban is perfect for teams that need to balance continuous delivery with changing priorities. It provides clarity and focus, making it a go-to for DevOps, content creation, and operations teams.

Business Process Reengineering (BPR) isn’t about small tweaks; it’s a radical redesign of core business processes to achieve dramatic improvements in productivity, cycle times, and quality. Instead of incrementally improving an existing process, BPR starts with a blank slate and asks, “If we were starting this company today, how would we do this?” It’s a complete overhaul, often driven by new technological capabilities.

This approach is one of the most transformative process innovations examples because it forces an organization to question its long-held assumptions and redesign workflows around outcomes, not tasks. BPR challenges the “this is how we’ve always done it” mentality, aiming for quantum leaps in performance rather than minor gains.

A rapidly growing tech consultancy found its hiring process couldn’t keep up with demand. The process was a linear, multi-stage pipeline involving recruiters, hiring managers, and technical interviewers, often taking over 60 days to make an offer. They decided to reengineer it completely. Instead of a sequential process, they created a “Hiring Hub” model. For a specific role, all key decision-makers would block out a single day. Candidates would go through all interview stages—from screening to technical assessment to final culture-fit—in one session. The team would then deliberate and make a hiring decision by the end of the day. This radical redesign cut the time-to-hire from 60 days to less than a week, dramatically improving their ability to land top talent in a competitive market.

BPR is a high-risk, high-reward strategy best suited for processes that are fundamentally broken or hopelessly inefficient, not those that just need a minor tune-up.

Kaizen is less of a single project and more of a cultural shift. This Japanese philosophy centers on making small, incremental improvements to processes continuously over time. Instead of waiting for a massive, disruptive overhaul, Kaizen empowers every employee, from the CEO to the front-line worker, to identify and eliminate waste in their daily tasks.

This approach is one of the most powerful process innovations examples because it builds a self-sustaining engine for efficiency. It’s not a one-and-done software implementation; it’s a mindset that embeds optimization into the very fabric of your company’s operations, promoting collaboration and collective ownership of process quality.

A data science team at a consulting firm adopted a Kaizen approach to their project workflow. They started a weekly “Process Improvement” meeting that lasted just 30 minutes. In one meeting, a junior analyst suggested that the team was wasting time setting up project environments from scratch for every new client. The team agreed and decided to create a standardized project template in their data science platform. This small change saved each data scientist several hours per project. Over the months, other small improvements—like creating a shared library of reusable code snippets and standardizing reporting formats—compounded. These incremental changes significantly reduced project setup time and improved the consistency and quality of their deliverables.

Kaizen thrives in environments where employee feedback is valued and acted upon. It’s perfect for mature processes where revolutionary change is risky, but incremental gains can compound into significant long-term advantages.

| Method | 🔄 Implementation complexity | ⚡ Resource & speed | 📊 Expected outcomes / impact | 💡 Ideal use cases | ⭐ Key advantages |

|---|---|---|---|---|---|

| Lean Manufacturing | Moderate–high: cultural change and phased rollout | Moderate: training + process changes; improves lead time | Reduced waste, lower costs, higher throughput & quality | Manufacturing, supply chain, repeatable production lines | Efficiency gains, quality consistency, employee involvement |

| Six Sigma | High: statistical rigor, structured programs and certification | High: significant training/time; slower initial wins but measurable ROI | Dramatic defect reduction, measurable financial benefits | Quality-critical processes (manufacturing, finance, healthcare) | Data-driven problem solving, measurable ROI |

| Business Process Management (BPM) | High: requires IT integration, modeling and governance | High: software/licensing and implementation time; medium-term speed gains | Greater transparency, automation, compliance, improved cycle times | Cross-department workflows, regulated industries, complex processes | Holistic process control, real-time monitoring, automation |

| Agile Process Management | Low–moderate: team training and mindset shift; scaling is harder | Low–moderate: lightweight tooling; fast iterative delivery | Faster delivery, better responsiveness, reduced risk via early feedback | Software, product development, projects needing adaptability | Rapid value delivery, strong team collaboration |

| Total Quality Management (TQM) | High: organization-wide cultural transformation over years | High: sustained training and governance; slow-to-peak speed improvements | Long-term quality improvement, customer loyalty, reduced defects | Organizations aiming for enterprise-wide quality excellence | Broad quality focus, cultural and strategic improvement |

| Robotic Process Automation (RPA) | Low–moderate: technical setup but needs standardized processes | Moderate: low-code platforms; quick ROI and large speed boosts | Reduced manual work, faster processing, higher accuracy, cost savings | High-volume, rule-based admin tasks (finance, HR, customer service) | Fast automation of repetitive tasks, scalable 24/7 execution |

| Design Thinking | Moderate: requires user research, prototyping and iteration | Moderate–high: resource-intensive up-front; reduces long-term risk | User-aligned innovations, higher adoption, improved UX | New product/process design, customer experience improvements | Human-centered solutions, rapid prototyping to reduce failure risk |

| Kanban System | Low: simple visual board adoption; minimal tooling | Low: quick to implement; improves flow and cycle time rapidly | Improved visibility, reduced WIP, faster throughput at team level | Team-level workflow management, maintenance, small projects | Simplicity, flexibility, rapid identification of bottlenecks |

| Business Process Reengineering (BPR) | Very high: radical redesign, restructuring and high risk | Very high: large resource investment; potential for rapid large gains | Dramatic performance improvements or disruption; large cost reduction | When incremental change insufficient; major transformations | Potential for step-change performance and competitive differentiation |

| Continuous Improvement (Kaizen) | Low–moderate: ongoing cultural discipline and daily practices | Low: low-cost, incremental changes; slow but compounding speed gains | Sustained small gains, improved morale, cumulative efficiency | Organizations seeking steady improvement and employee engagement | Low-risk, sustainable improvements and strong employee ownership |

We’ve journeyed through a landscape rich with process innovations examples, from the disciplined frameworks of Lean Manufacturing and Six Sigma to the dynamic, human-centric approaches of Design Thinking and Agile. We’ve seen how Robotic Process Automation (RPA) can obliterate mundane tasks and how a philosophy of Continuous Improvement (Kaizen) can create a culture of excellence.

The single most important thread connecting all these successful examples is this: innovation isn’t a one-size-fits-all solution. It’s a strategic choice. The goal isn’t to adopt every new technology or methodology. The real goal is to diagnose your specific operational pains and prescribe the right remedy.

Before charting your course, let’s distill the key takeaways from the examples we’ve explored. True process transformation hinges on a few fundamental truths:

Feeling inspired is one thing; taking action is another. It’s easy to get overwhelmed by the possibilities. Here’s a simple, three-step framework to move from idea to implementation, helping you apply these process innovations examples to your own organization.

Strategic Insight: The true power of process innovation lies not in a single grand gesture, but in the cumulative effect of many intelligent, targeted improvements. Your first project doesn’t need to be perfect; it just needs to deliver measurable value and create a blueprint for what’s next.

Mastering these concepts is more than just an operational upgrade; it’s a competitive advantage. In a world where speed, efficiency, and customer value are paramount, your processes are your engine for growth. By continuously refining how you work, you build a resilient, agile organization that can not only weather change but thrive on it. The journey starts with a single step, a single process, and a commitment to making it better.

Ready to move from exploring process innovations examples to implementing a tailored solution? NILG.AI specializes in diagnosing core business challenges and deploying custom AI and data strategies that drive real efficiency and growth. Let’s build your innovation roadmap together. Request a proposal

Like this story?

Special offers, latest news and quality content in your inbox.

Feb 10, 2026 in Listicle: Examples

Discover digital business transformation examples and how AI, data, and strategy fuel growth with practical, actionable insights.

Feb 6, 2026 in Resources

Discover the 12 best AI tools for small business success. Our guide covers strategic insights, pros & cons, and how to choose the right AI partner.

Feb 3, 2026 in Guide: How-to

Master customer retention rate calculation with this practical guide. Learn the formulas, see real-world examples, and get actionable tips for business growth.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |